-

WhatsApp +8619952575698

-

Address Nantong City, Jiangsu, China

Hydraulic system

The ship hydraulic system product description is as follows:

A ship hydraulic system is a system that converts the pressure and fluidity of a liquid fluid (such as water or hydraulic oil) into mechanical power. It is an important component in ship engineering and is widely used in the control, transmission, and lifting of various mechanical equipment on ships.

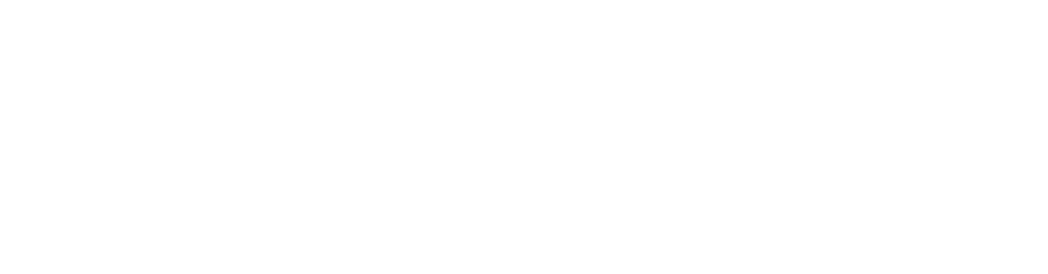

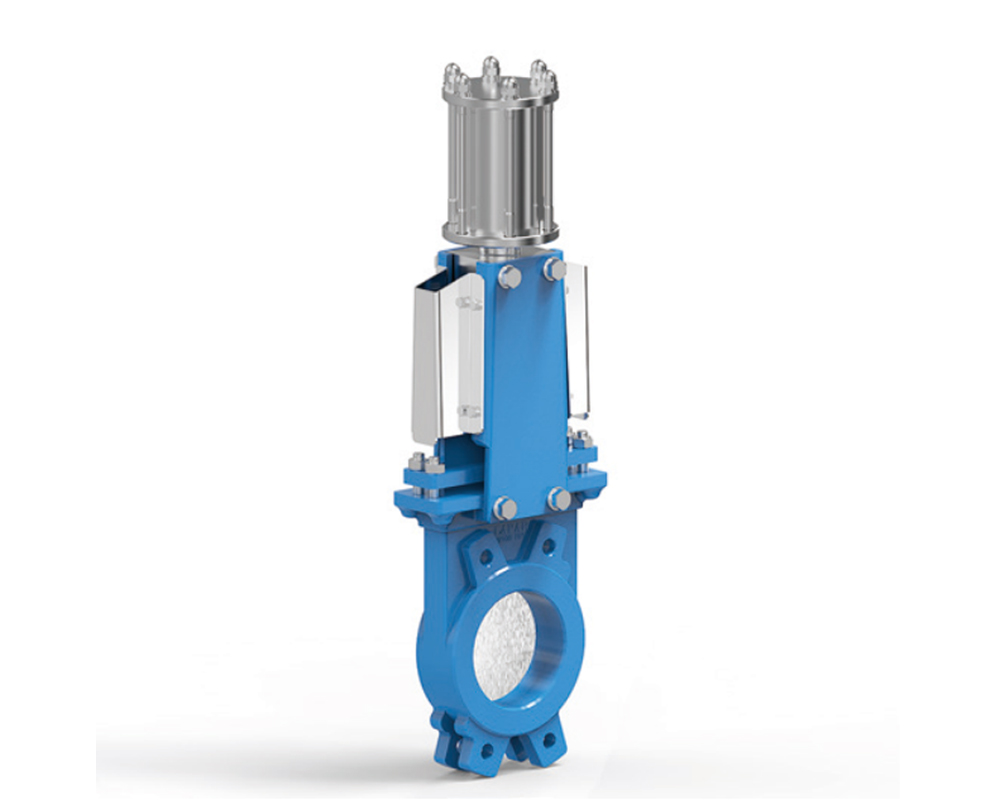

The components of ship hydraulic system include pressure source, controller and actuator. The pressure source is mainly composed of hydraulic pumps, electric pumps, etc., and is the power source in the hydraulic system. Controllers are usually composed of valves, actuators, control components and electrical appliances, and are used to control the direction, pressure and flow of fluids. The actuator includes equipment such as cylinder liners, oil cylinders, hydraulic motors, and pressure beams, which are responsible for converting the energy of the hydraulic system into mechanical energy.

Marine hydraulic systems have a wide range of applications. It can be used to control the direction and rudder of the ship, lift the ship's anchor and mast, and drive the boom of the crane, etc. For high-speed vessels, the hydraulic system can also be used to control the direction and speed of the propeller, increasing the vessel's maneuverability and stability. In addition, in underwater operations, hydraulic systems can also be used to drive underwater equipment such as submersible pumps and submersibles.

Compared with mechanical transmission systems, marine hydraulic systems have the following advantages:

1. Space saving: Since high-pressure components and actuators are typically smaller, hydraulic systems are easier to install in tight spaces.

2. Stronger control capability: The controller of the hydraulic system can change the direction and flow of the fluid in an instant, and control the force and displacement generated by the actuator in real time, making the ship more stable and easier to control.

3. Durable and reliable: The hydraulic system has high reliability and durability and can meet the needs of ships in various harsh environments.

4. Low energy consumption: The hydraulic system has low energy consumption and meets the requirements of energy conservation and environmental protection.

5. Coordinated layout and convenient management: The components and pipelines of the hydraulic system are usually carefully designed and arranged, making the entire system coordinated and orderly, and easy to manage and maintain.

6. System cleaning: Hydraulic systems have high requirements for liquid cleanliness, which can ensure the normal operation of the system and extend its service life.

7. Electro-hydraulic integration: Modern ship hydraulic systems also have electro-hydraulic integration functions, which can achieve more precise and intelligent control through electronic control.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.