-

WhatsApp +8619952575698

-

Address Nantong City, Jiangsu, China

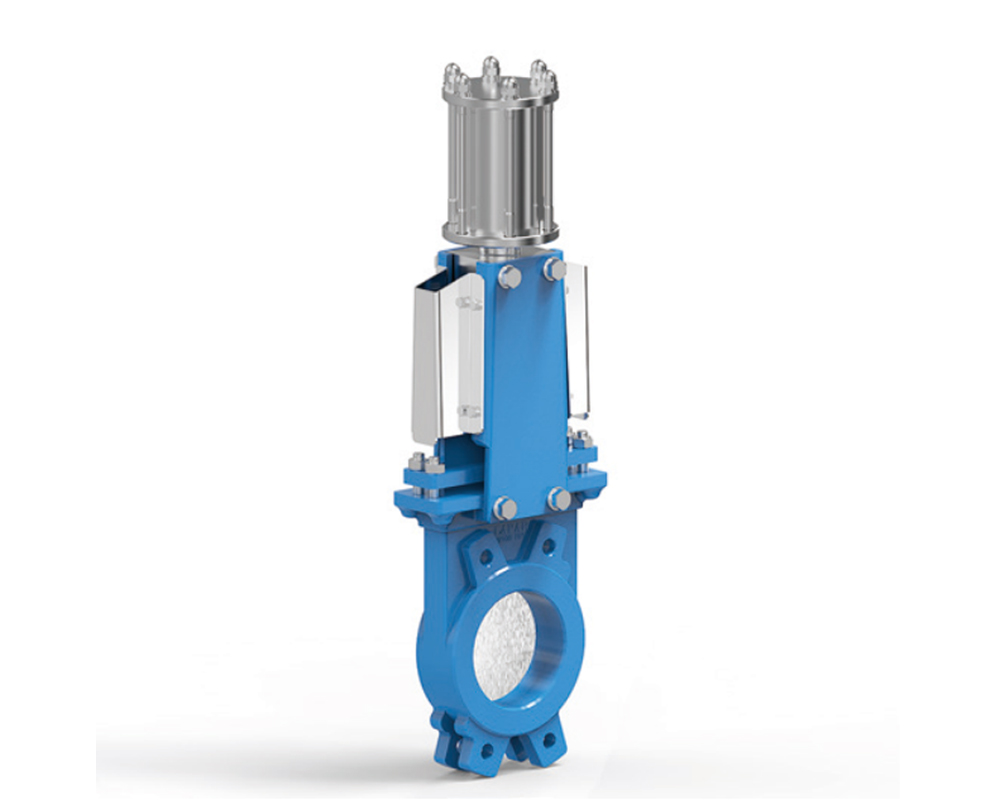

LPL11-Knife gate valve

Knife gate valve, also known as knife gate valve, knife gate valve, slurry valve and mud valve, mainly relies on the gate to control the flow and closure of the medium. The movement direction of the gate is perpendicular to the direction of the fluid. The special feature is its blade-shaped gate design, which can cut fiber materials and effectively cut off the medium.

The gate plate of the knife gate valve has two sealing surfaces. Usually these two sealing surfaces form a wedge shape, and the wedge angle will vary according to the specific parameters of the valve. According to needs, the gate of the wedge-type knife gate valve can be made into a whole, which is called a rigid gate; it can also be designed to produce a slight deformation of the gate. This design is mainly used to improve the processability and make up for the sealing surface. Possible deviations in angle during processing.

It is worth noting that there is actually no cavity in the valve body of the knife gate valve. The gate plate rises and falls in the side guide groove and is pressed against the valve seat by the lugs at the bottom. If higher media tightness is required, an O-ring sealing valve seat can be selected to achieve bidirectional sealing.

Knife gate valve has its unique advantages in application. First of all, it has a small installation space, and the working pressure is relatively low, and it is not easy to accumulate debris. Secondly, its price is relatively affordable.

When closing, the sealing surface of the knife gate valve can achieve sealing by relying only on the medium pressure, which is the so-called self-sealing. Most gate valves use forced sealing, that is, when the valve is closed, external force is required to force the gate plate to the valve seat to ensure the sealing performance of the sealing surface. In use, such valves should generally be installed vertically in pipelines.

In addition, knife gate valves are suitable for a variety of media, such as pulp, coal ash, chemical raw materials, sewage and food. Its working pressure range is usually within 1.6MPa, and its working temperature is generally below 120°C. If necessary, special materials can also be used to cope with high temperature environments.

In general, knife gate valves have significant advantages such as light switching, reliable sealing, good elastic memory and long service life. It is widely used in various pipeline lines such as tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electric power, shipbuilding, metallurgy, energy systems, etc., as a regulating and intercepting device.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.