-

WhatsApp +8619952575698

-

Address Nantong City, Jiangsu, China

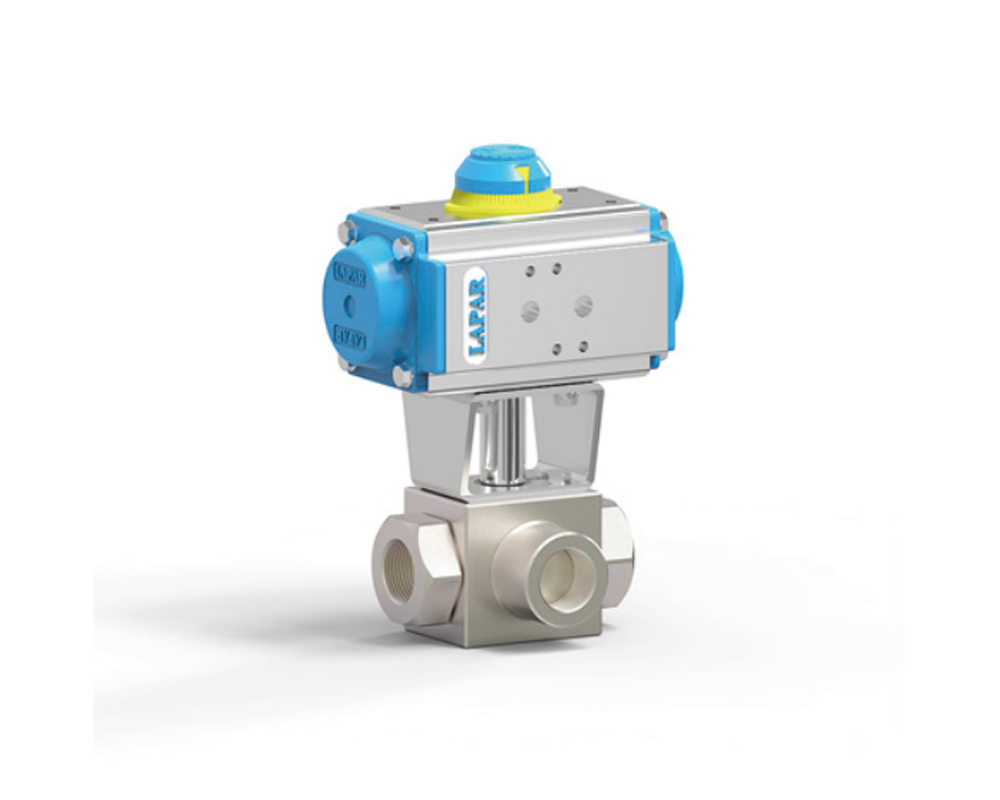

LPA12-,15-Threaded, butt weld ball valve

Threaded/butt welding ball valve product introduction is as follows:

This ball valve adopts butt welding connection method and is suitable for industrial sectors such as petroleum, natural gas, liquefied petroleum gas, liquefied natural gas, chemical industry, and environmental protection. Its working pressure range is wide, from ANSI Class 150 to 2500, PN 16 to 420. Flexible operation methods include handle, gear (vertical/horizontal) and electric mode. In addition, the product's adaptable operating temperature range is also very wide, from -29℃ (-20℉) to +200℃ (392℉).

Structurally, the ball valve adopts a solid structure, and the valve stem has automatic lubrication capability without the need for additional lubricant. Its antistatic device ensures safe operation. In addition, the valve is available in a variety of special designs, such as floating or fixed ball valves, self-rescuing valve seats, vertical devices and extended stems, special ports and orifices, safety fireproof designs with graphite gaskets, etc.

In terms of material, the body of this ball valve is made of carbon steel ST37, A106-B, STPG 370, A105, ASTM A516-60 or A216-WCB, etc., the ball is made of stainless steel 304 or 316, and the valve seat is made of metal with polymer Sealing rings, such as PTFE, RTFE, Viton, Nylon or Peek, etc.

In short, the threaded/butt welding ball valve is a high-quality valve product with the advantages of high efficiency, safety and reliability. The above is for reference only. If you need more information, it is recommended to visit the official website of the relevant brand or consult with industry insiders.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.