-

WhatsApp +8619952575698

-

Address Nantong City, Jiangsu, China

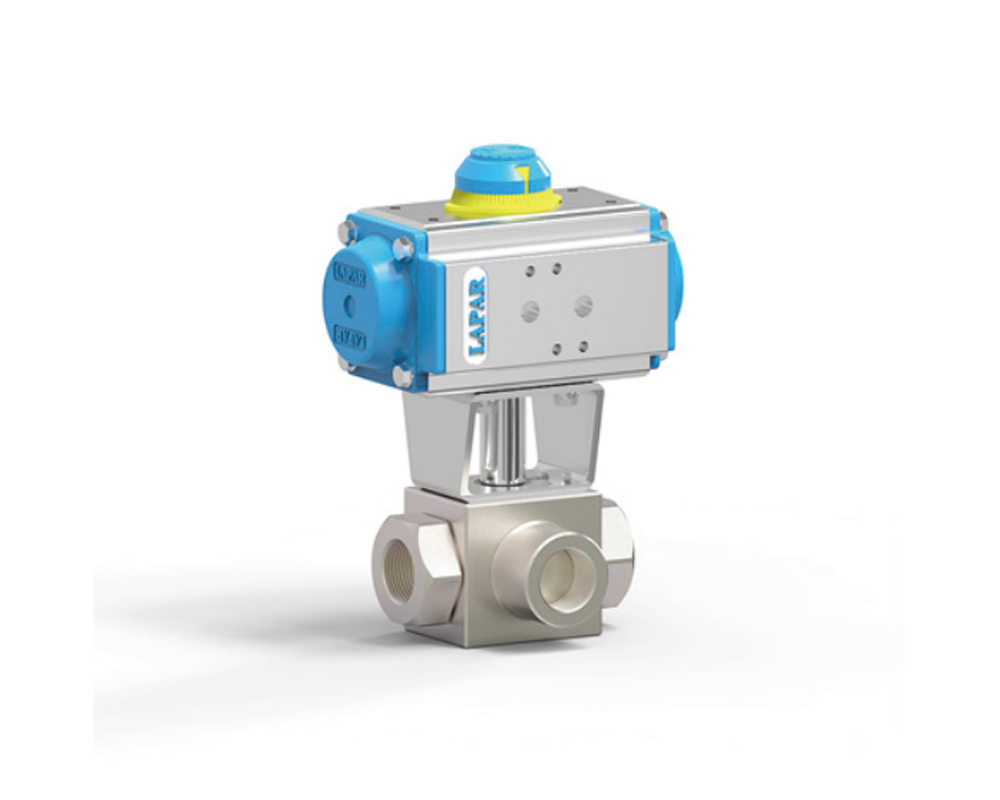

LPA18-Metal seal ball valve

Metal-sealed ball valve is a valve whose sealing surfaces of the ball and valve seat are precision machined and have high grinding accuracy. This design allows the ball and seat to be freely interchanged (if they are of the same caliber). Other features include a scraper-type self-cleaning function that removes adhering particles, reduces seat leakage and extends valve life.

Metal-seated ball valves are typically tested with nitrogen at 300 psig for 60 minutes to ensure they meet the fairly high standards required for leak protection in shut-off service. Its product features include:

1. ASME standard diameter:” ~ 16”.

2. Pressure level: Class 600 ~ Class 4500.

3. Full diameter or reduced diameter structure.

4. Two-piece valve body design, carbon steel or stainless steel material.

5. Fire design complies with API-607, Exxon and TUV standards.

6. Bubble sealing grade.

In addition, metal-sealed ball valves are also widely used in coal chemical, polysilicon, mining, metallurgy, oil refining and chemical industries. The working conditions in these industries are complex and harsh, including high temperature, high pressure, and conditions containing hard solid particles, especially those containing hard solid particles. Liquid conditions for particles.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.