-

WhatsApp +8619952575698

-

Address Nantong City, Jiangsu, China

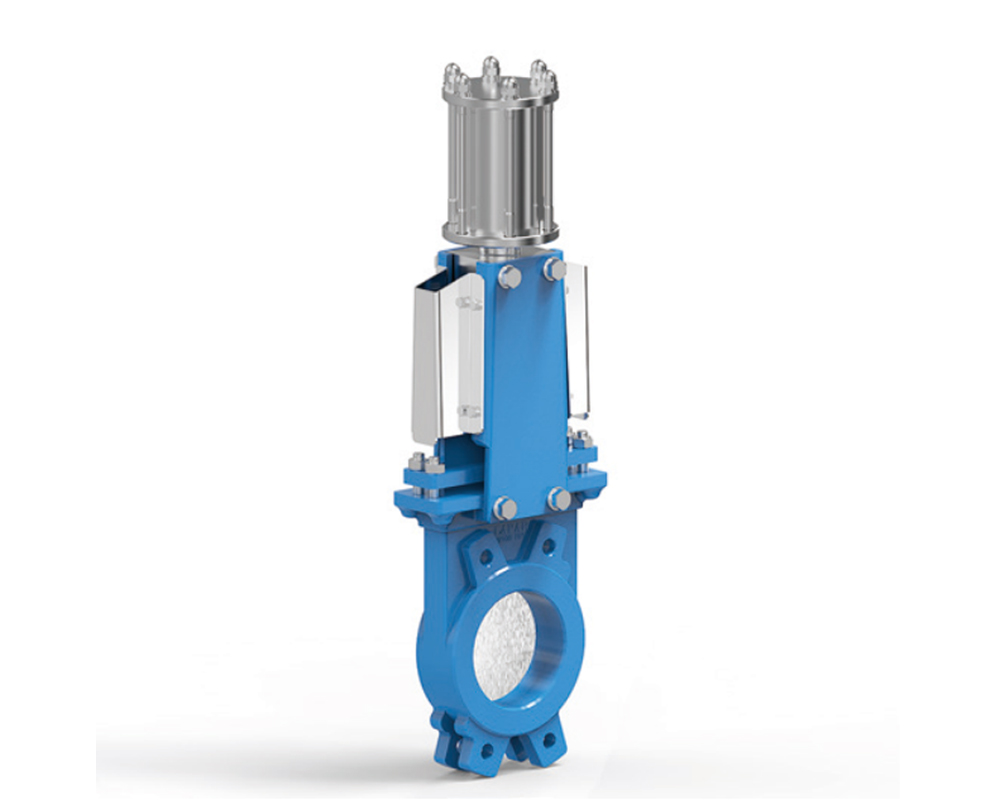

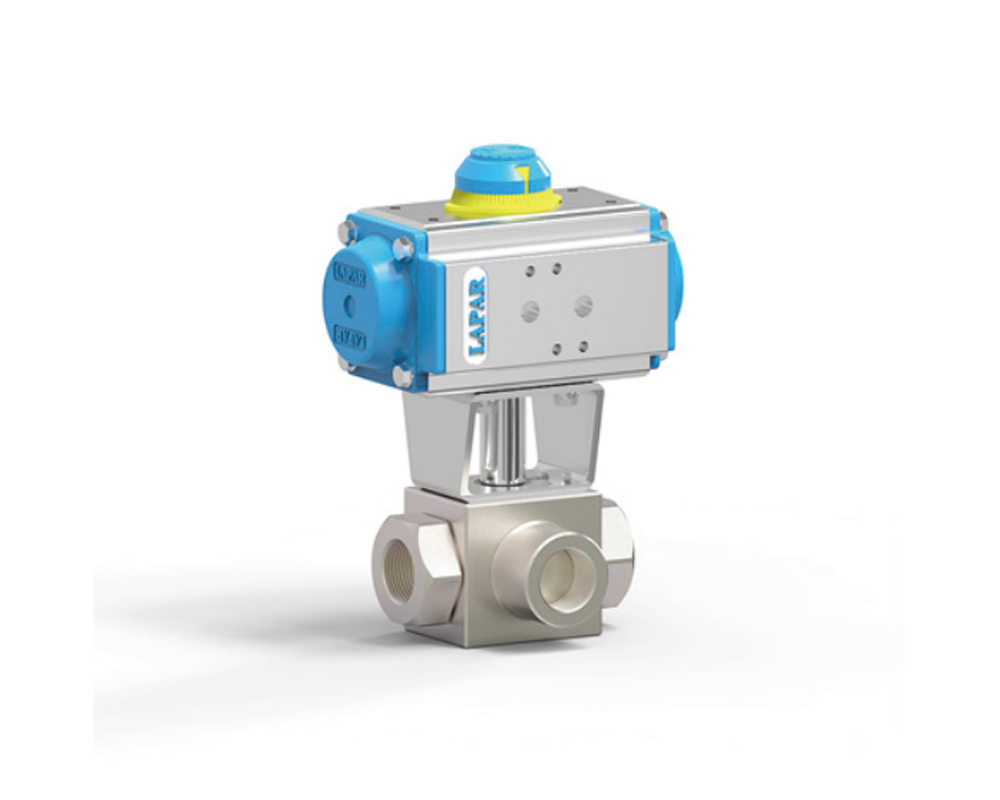

LPB12-Triple eccentric metal seal butterfly valve

Triple eccentric metal seal butterfly valve is a relatively advanced valve technology. The design feature of this kind of valve is that it has three eccentricities, that is, during the opening and closing process of the valve plate, the center of the valve plate and the center of the sealing surface do not coincide, but there is a certain eccentricity. In addition, the sealing material of the valve is made of metal, which has good resistance to high temperature, high pressure, corrosion and wear.

Structurally, the valve body and valve seat of the triple eccentric metal seal butterfly valve are designed as one-piece components, and the valve seat sealing surface layer is overlayed with temperature-resistant and corrosion-resistant alloy materials. Multi-layer soft stacked sealing rings are fixed on the valve plate. This design ensures that the valve has no friction during the opening and closing process and has good sealing performance. In addition, as the torque of the transmission mechanism increases, the sealing performance is further compensated, thereby increasing the service life of the valve.

However, the triple eccentric metal seal butterfly valve also has some limitations. Due to its structural characteristics, this kind of valve is not suitable for valves with a diameter below DN200, because the overall structure of the valve plate is too thick and the flow resistance is large. In addition, due to the principle of the triple eccentric structure, the seal between the sealing surface of the valve plate and the valve seat relies on the torque of the transmission device to press the valve plate against the valve seat. When the flow channel medium flows back, as the medium pressure increases, the unit positive pressure between the valve plate and the valve seat may be less than the medium pressure, causing the seal to begin to leak.

In order to solve this problem, some high-performance three-eccentric two-way hard-seal butterfly valves have adopted some improvement measures in their design. For example, the valve seat sealing ring can be composed of a soft T-shaped sealing ring and multiple layers of stainless steel sheets on both sides. This design can improve the sealing performance and stability of the valve, making it better adaptable to various complex working conditions.

In short, the triple eccentric metal seal butterfly valve is a valve technology with excellent performance, especially suitable for severe working conditions such as high temperature, high pressure, corrosion and wear. Through continuous technological innovation and improvement, it is believed that this kind of valve will be more widely used and developed in the future.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.