-

WhatsApp +8619952575698

-

Address Nantong City, Jiangsu, China

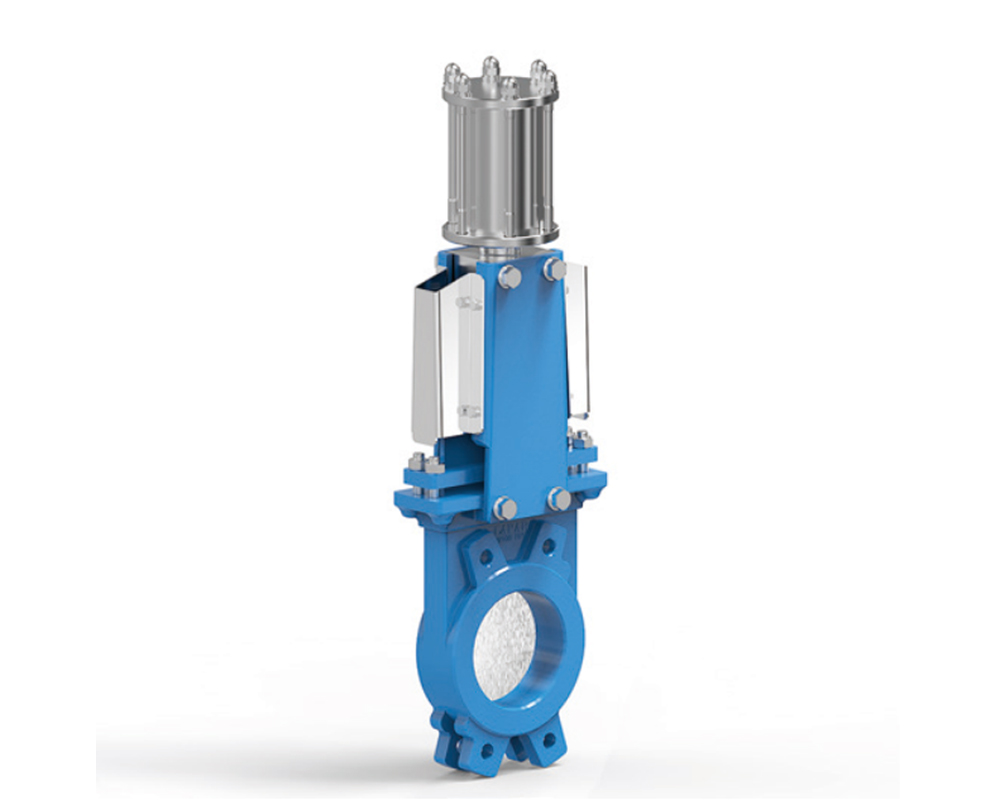

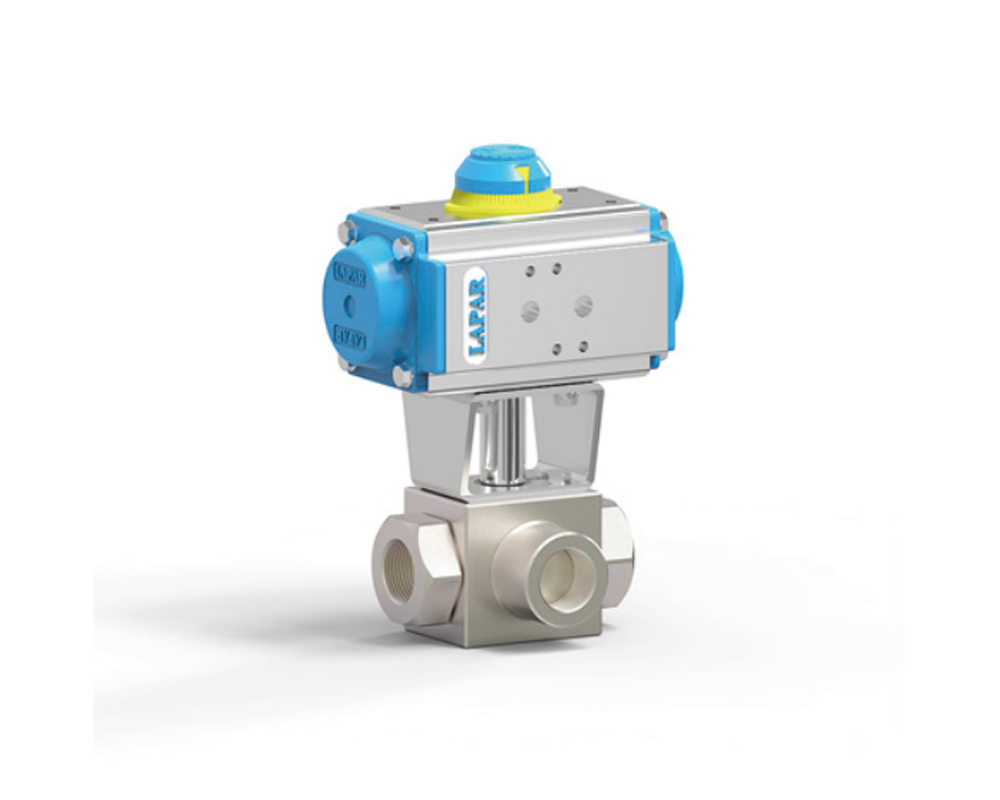

LPB14-High performance butterfly valve

High-performance butterfly valve is a special type of valve that occupies an important position in the industrial field due to its excellent performance and wide range of applications. The following is a detailed introduction to high-performance butterfly valves:

1. Structure and working principle:

High-performance butterfly valves are mainly composed of valve body, valve plate (butterfly plate), valve stem, bearings and driving device. Its working principle is to rotate the valve stem to drive the valve plate to rotate inside the valve body to open and close the valve. When the valve plate is closed, the high-performance butterfly valve can prevent the flow of fluid; when the valve plate is open, the fluid can flow from one side of the valve plate to the other side.

2. Features:

(1) High-performance butterfly valve has excellent fluid control characteristics and can effectively regulate the flow and pressure of fluid.

(2) Due to its simple and compact structure, high-performance butterfly valves are very convenient to install and maintain.

(3) High-performance butterfly valves can be applied to various working environments, such as high temperature, high pressure, vacuum, corrosive and other environments.

(4) High-performance butterfly valves have a long service life and reliability, and can ensure long-term and stable operation.

3. Application areas:

High-performance butterfly valves are widely used in various industrial fields, such as petroleum, chemical industry, electric power, pharmaceuticals, food, environmental protection, etc. Its main purpose is to control the flow, pressure, flow direction and other parameters of various fluids (gas, liquid), and realize functions such as fluid transportation, distribution and discharge.

4. Precautions for model selection and use:

(1) When selecting a high-performance butterfly valve, it is necessary to select the appropriate model and specification based on the actual working environment and working conditions.

(2) During use, the sealing performance of the valve and the lubrication of the bearings need to be checked regularly to ensure the normal operation of the valve.

(3) For corrosive fluids, corrosion-resistant materials need to be selected to manufacture valves.

(4) During use, the temperature and pressure of the fluid need to be strictly controlled to avoid damage to the valve caused by overtemperature and overpressure.

In short, high-performance butterfly valves, as an important fluid control equipment, play an increasingly important role in the industrial field. Understanding and mastering the structure, working principle, characteristics and application of high-performance butterfly valves will help to better use and maintain the valves and ensure the safety and stability of industrial production.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.